Features of CNC Nesting software

THE 9 ESSENTIAL FEATURES OF A GOOD CNC NESTING SOFTWARE

Nesting is one of the two main manufacturing processes used in the furniture industry, along with the point-to-point process. This process, which is predominantly used in North America, allows panel cutting and machining to be carried out in a single operation.

Why is the word Nesting used?

“Nest” refers to a bird’s nest. When a bird builds a nest, it cleverly fits many pieces of wood together in a small space. The industrial practice of nesting is the same. The principle is to fit as many workpieces as possible onto a single board.

Why does a company opt for the Nesting process?

- Time saving

- Reduction of manufacturing costs

- Compatibility with a pull production flow for customized manufacturing

- Great freedom of shape for parts and furniture

If you want to opt for a Nesting process in your company, we invite you to continue reading this article! We will detail the 9 must-have features that CNC nesting software must have to enable your industrial success.

9 – Optimal holding of small parts

8 – Program the labelling of parts automatically

7 – Optimise wood boards that are not completely interlocked

6 – Grouping parts of the same piece of furniture on a single board

5 – Manage the different materials of the boards

3 – Export the nesting result directly into a CAM software and program the machining operations

2 – Opt for a software that is easy to use and adapted to your company

9 - OPTIMAL HOLDING OF SMALL PARTS

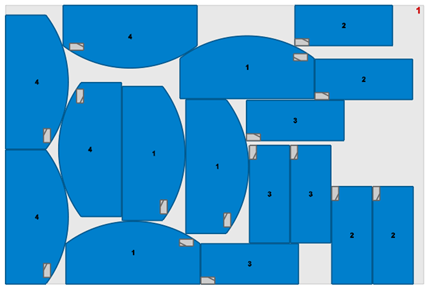

Most CNC Nesting machines hold the workpieces using a nested-based flat table. This system allows maximum holding before the machining phase begins. However, when small parts are machined with a tiny contact surface, the suction may not be strong enough to hold them on the flat table and the parts may detach/lose their hold when the cutter passes around them.

To overcome this problem, SWOOD Nesting and SWOOD CAM propose to integrate material “bridges” between surrounding parts. This creates a coherent set of parts. These “bridges” can be machined in the last pass or removed manually.

SWOOD 2022 brings two new features that improve the holding of small parts/

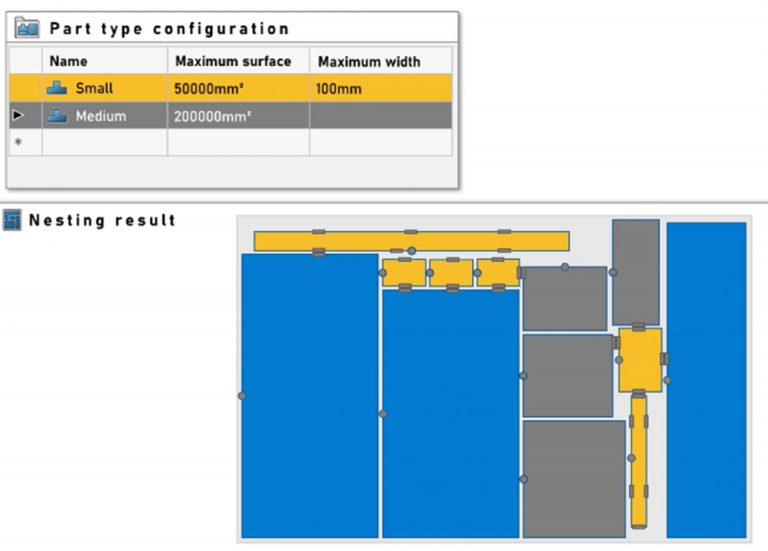

1 – Pre-define strategies based on part types

With SWOOD Nesting 2022, it is possible to define a part as a “small part” if it is below a certain area or width and force the program to machine these small parts at the end of the whole process. It is also possible to force these small parts to be placed at a certain distance from the edges of the board. You can also automatically insert “bridges” depending on the type of part.

2 – Forcing a one-step machining operation on the entire board

SWOOD CAM 2022 offers a new machining operation specific to Nesting: “Staydown Contour”. This operation automatically detects the contour of all nested parts on the board and schedules a single tool pass to keep the parts on the board as long as possible.

8 - PROGRAM THE LABELLING OF PARTS AUTOMATICALLY

Once machined, two near-identical parts can be mistaken for each other and incorrectly routed. Some nesting machine manufacturers offer labelling machines that place labels on the board before the machining begins.

SWOOD 2022 incorporates new functionalities to manage label positioning with custom parameters, such as offset from the part edge, gap avoidance, or manual label repositioning.

7 - OPTIMISE WOOD BOARDS THAT ARE NOT COMPLETELY INTERLOCKED

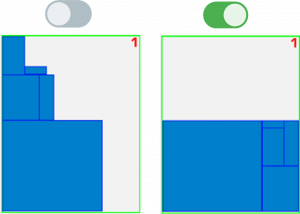

Sometimes, the interlocking parts do not use the entire surface of the board. Two strategies can be considered:

1 – Condense the nesting as much as possible on one side of the board to recover all usable scrap

SWOOD Nesting offers an option that compares the two nesting directions (X and Y) and selects the most optimal.

2 – Adding “bonus” filler parts to build up stock

Companies often have small parts to produce in large quantities. So, instead of creating specific nesting for these small parts, why not integrate them into each nesting to fill the boards? SWOOD Nesting offers this possibility!

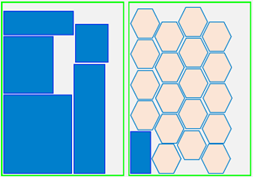

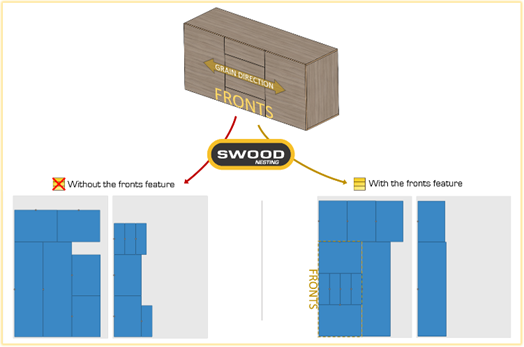

6 - GROUPING PARTS OF THE SAME PIECE OF FURNITURE ON A SINGLE BOARD

With the Nesting process, parts of the same piece of furniture may be positioned on different boards. This can lead to a loss of time for your teams, as they must wait for all the boards to be machined before assembling the furniture.

To overcome this problem, SWOOD Nesting proposes to group all the parts of a piece of furniture on the same board.

This feature, therefore, allows you to group the parts of a piece of furniture for which you want to monitor the grain direction. This is important for aesthetic reasons on furniture fronts. Therefore, this group of parts is treated as a single board in the nesting.

5 - MANAGE THE DIFFERENT MATERIALS OF THE BOARDS

CNC nesting software must be able to manage the differences in materials between boards and match the respective parts to be machined accordingly based on their materials. The software must also allow the supplier references and the purchase price of these boards to be entered to know their costs.

Besides these essential functions, SWOOD goes even further:

- Exclude certain machines for certain boards. With SWOOD CAM, companies that use several nesting machines of different sizes can allocate certain boards to machines.

- Recover the dimensions of the primary waste and reuse it for further machining. As explained earlier (N°6), nesting results can lead to boards that are not filled. SWOOD Nesting allows you to retrieve the remaining board waste size when generating the report and integrate this value into your company’s ERP system.

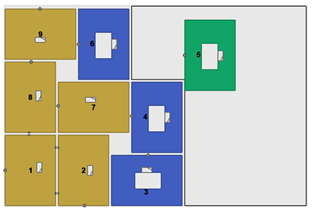

4 - IMPROVE MANUAL NESTING

Many manufacturers who have used CNC nesting software have found themselves faced with a nesting output they wished they could modify.

With SWOOD Nesting, it is possible to manually modify the position (and angle) of parts on an already nested board. This feature allows you to make any changes you want to the positioning of your parts.

SWOOD Nesting also offers the possibility of manually choosing the machining order in case the automatically proposed order does not suit you.

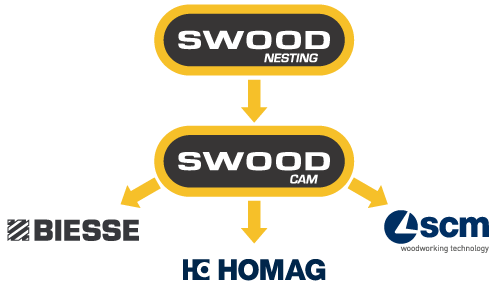

3 - EXPORT THE NESTING RESULT DIRECTLY INTO A CAM SOFTWARE AND PROGRAM THE MACHINING OPERATIONS

If your nesting software is well set up, it can save you a lot of time by automatically arranging all the parts to be manufactured on the boards, thus reducing material loss to a minimum. If this software is not linked to your CAM software, your company will lose considerable time importing nesting results to allocate the machining operations. The initial time saving generated by the nesting software is lost.

Therefore, after creating a nesting layout with SWOOD Nesting, it is possible to automatically switch to SWOOD CAM and assign the nesting-related machining operations (drilling, contouring, pockets, etc.) by simple drag-and-drop.

As SWOOD is not dependent on any specific brand of CNC machine, machining programs can be created for machines of different brands.

With SWOOD Nesting 2022, it is even possible to integrate automatic default machining operations into the nesting result. No more drag and drop machining operations!

2 - OPT FOR A SOFTWARE THAT IS EASY TO USE AND ADAPTED TO YOUR COMPANY

A good software should meet the needs of your business and be easy to use. When choosing your Nesting software, make sure that the interface is user-friendly, the settings are instinctive, and that all the features are adapted to your needs.

With SWOOD, you can fully customize the different features of the software to build a tool that is almost tailor-made for your needs. Our teams also offer specific training courses to help you become familiar with the software. We can offer you a unique version of SWOOD that is fully adapted and customized for your company (bill of materials, cost list, program lists, labels, etc.).

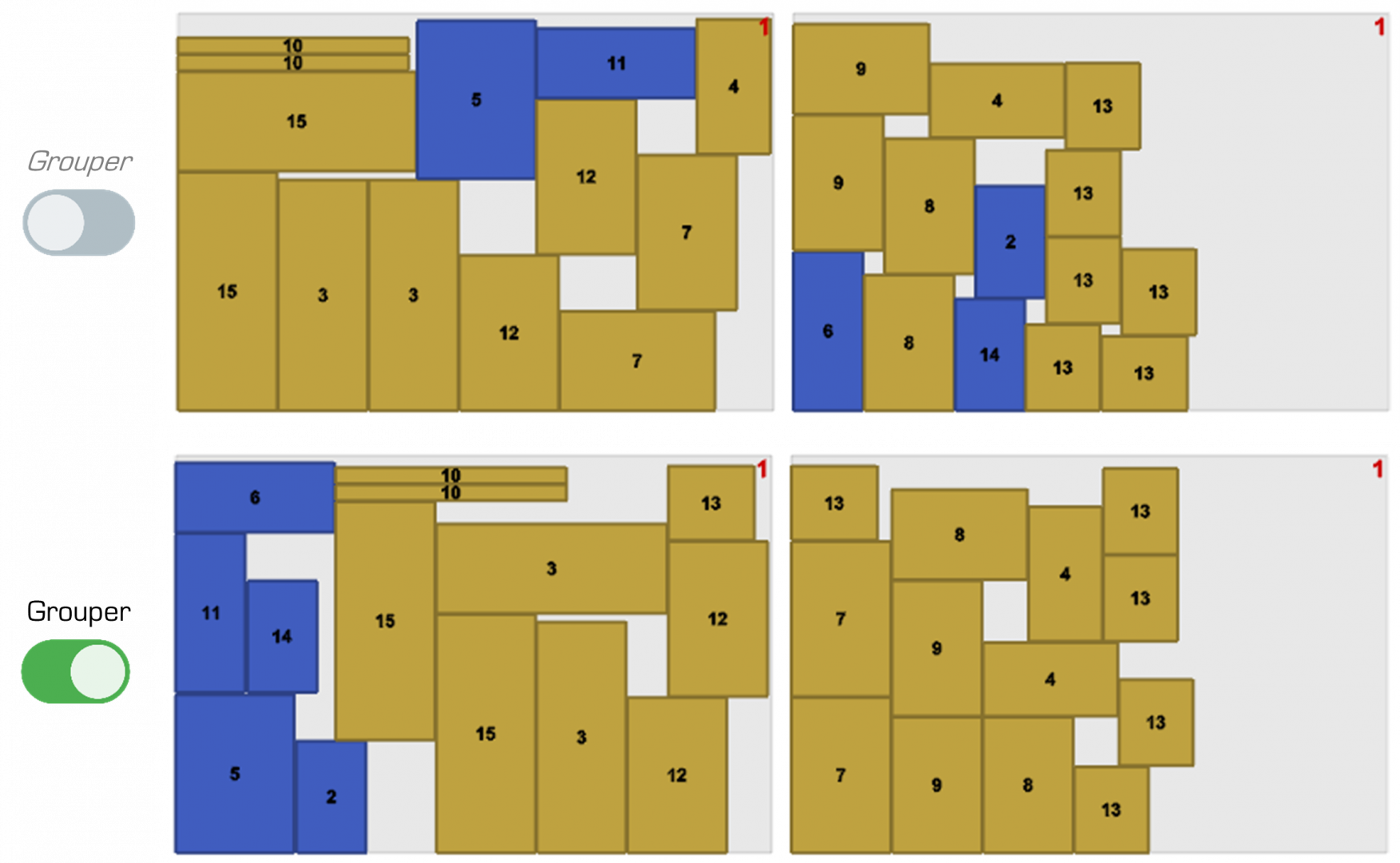

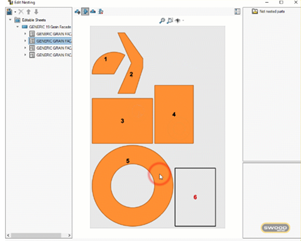

1 - REFINE THE NESTING ALGORITHM PARAMETERS

The most critical function of CNC nesting software is the variety of parameters that need to be set to get a satisfactory result. A nesting algorithm can seem like a “black box” that pulls a nesting result out of thin air.

With SWOOD Nesting, all nesting parameters are visible and modifiable. Some parameters are common to general nesting algorithms (rectangular nesting, angle of rotation, integration of parts into parts, etc.) and others are specific to the wood industry (grain direction, the orientation of fronts, etc.). Users can therefore predict their nesting results in advance.

With SWOOD Nesting 2022, it is possible to define different parts according to their size and set rules accordingly. For example, all parts with a dimension of less than 200mm are considered “small”. They will be placed in the center of the board and machined last.

The 9 must-have features of Nesting software are now familiar to you!

Go to our SWOOD Nesting page to know more about our Nesting solution!