ÜÇGE provides innovative solutions for retail, logistics, and industrial sectors. For 47 years, they have established themselves as a trusted supplier of store equipment, warehouse shelving systems, smart storage solutions, digital systems, and environmental solutions. Their reach extends to 92 countries, operating from Europe’s largest integrated facilities. ÜÇGE prioritizes customer satisfaction by developing products based on innovation, technology, digital transformation, and sustainability. With a network of 10 companies, 6 factories in Bursa (Turkey), a warehouse and office in Germany, and over 40 distributors worldwide, ÜÇGE employs over 750 people dedicated to exceeding customer expectations

About ÜÇGE

Industry – Retail

Size – +750

Location – Bursa,Turkey

Products used – SWOOD Design, SWOOD CAM

Sales partner – TEKYAZ

A Customer’s Need for Speed

In the retail industry, speed is a key advantage. Customers require a quick design process that results in accurate production. ÜÇGE, a company that specializes in boutique retail, used to draw their products as a whole and measure connector locations individually. This method was both time-consuming and a risk for errors. Samet Ersin, a member of ÜÇGE’s design department, highlights the industry expectations: ” In boutique retailing, our customers want speed in every area. Our duty is to design as soon as possible and accurately transmit the images/data of solid models and sub-parts to production.”

In some cases, late change requests may slow down the design process. Samet Esrin precise: “Since all parts were interconnected, deleting one part would negatively affect the entire design.” These types of situations cannot be entirely predicted in advance, as they depend on the customer’s preferences.

ÜÇGE: A Request for Assistance

On top of aiming to streamline their processes, ÜÇGE required a solution able to adapt to different expertise for the same project; as Fatih Katip, Design and Method Manager, says: “There are many dynamic variables in the design aspect of our industry as different materials are used on the products… It is very difficult to bring all these materials together properly and turn them into products, and all these engineering processes require professionalism”. In order to effectively work with various materials, it is important to have a reliable management tool.

UCGE recognized the need to automate production for efficiency, as Erkan Kaya from the production department highlighted: “The biggest difficulty was that we put a lot of effort into setting the program correctly while performing blade assignment operations on complex data. Skipping the drilling and milling operations on the parts caused problems in the next operation.” During the production process, time and effort were lost due to manual actions that could be optimized.

SWOOD: A Solution for Efficiency

For the past four years, ÜÇGE has successfully overcome these challenges by implementing SWOOD. Fatih Katip explains that there has been a significant impact in their processes: “With the help of boxes, our design process has accelerated and is progressing without errors. At the same time, it provided ease of data transfer with CAM systems integration and optimized our workflow.” Their design process has been streamlined, and they are able to anticipate production with the SWOOD report system, resulting in a more efficient and productive workflow.

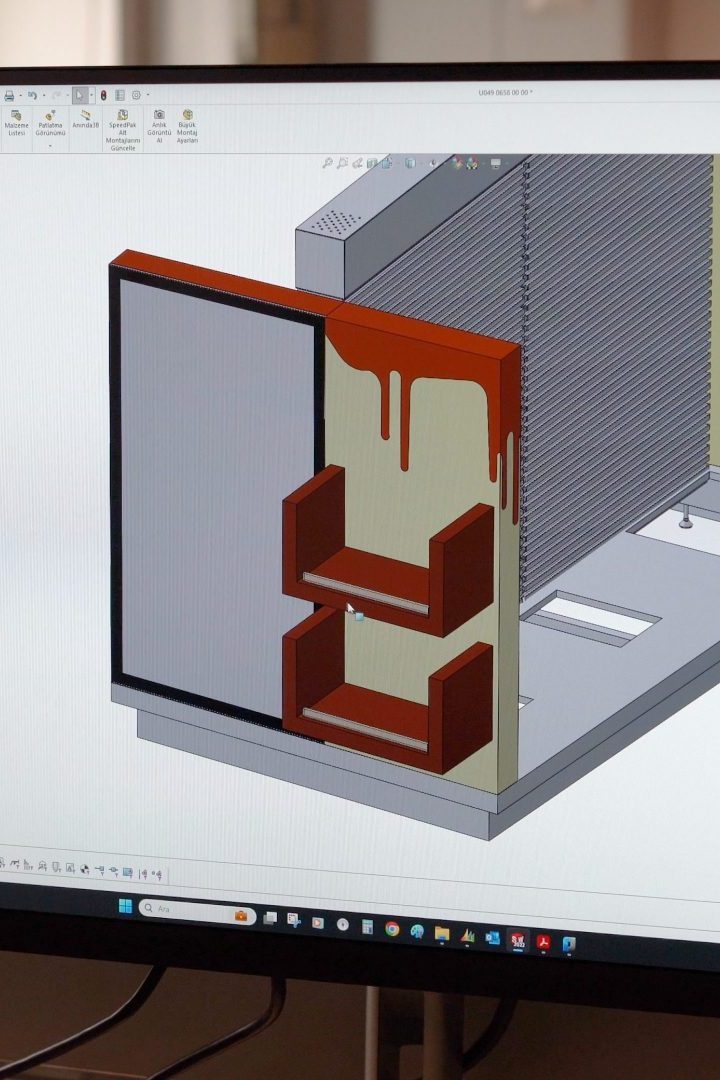

Being able to work in the SolidWorks environment was a game changer, allowing them to create complex furniture and make changes to specific locations, as well as the overall design; as Samet Esrin says: “We can quickly draw designs such as counters or cabinets in the assembly environment, where we can open each created piece and make the changes we want.” SWOOD has improved the way ÜÇGE communicates with its clients, leading to more efficient interactions.

Beyond Design

The benefits of SWOOD extend beyond the design department; the production team has also experienced significant improvements in its manufacturing process. Previously, operators faced challenges with blade assignment on complex data.

However, SWOOD’s automated process has optimized this step and significantly accelerated CAM processing. Erkan Kaya, from ÜÇGE’s production department, has highlighted this improvement, stating that ” after using SWOOD, we accelerated the CAM process by 80%, and our operator-related errors were eliminated. Instead of setting up a program, our operators put their energy into processing CNC parts during that time.” Thanks to SWOOD, they now have greater control over their process time and can easily manage other tasks.

Customer Satisfaction

ÜÇGE has observed an increase in customer satisfaction within the Shopfitting industry since implementing SWOOD; according to Fatih Katip, ” SWOOD software can speed up design processes, increase efficiency, and help achieve more effective results.”

SWOOD’s precision in generating material lists and production data promotes seamless collaboration between the design, production, and purchasing departments. Samet Ersin states, “Both production and purchasing proceed with the data we provide, and in this case, we can say that it is “problem-free” since the right product is delivered to our customers.” By utilizing this new system, ÜÇGE can improve the efficiency and accuracy of their services and offer better experiences for their clients.

SWOOD Impacts Overall: A Collaborative Future

ÜÇGE considers SWOOD and TEKYAZ team as valuable partners in their journey towards a more efficient future. They highly value the open nature of the solution and the continuous support from the SWOOD team. The ability to customize box libraries and continuously develop content allows ÜÇGE to move forward with SWOOD. Samet Ersin appreciates this collaborative approach: “… the support of the SWOOD team was always with us in developing our content according to the needs and expectations we may have over time. We develop and move forward together.”

The story of ÜÇGE illustrates how SWOOD supports companies with the complexities of the shopfitting industry. By streamlining design, removing risks of errors, and facilitating collaboration, SWOOD helps businesses like ÜÇGE to achieve greater efficiency, faster production times, and in the end, happier customers.