Company Size: +250 employees

Company location: Fort Worth, TX

Sector: Retail

The Marco Company value proposition

“In this industry, everyone has access to the same materials and equipment. So the differentiator becomes your level of service, speed of response, and creativity (solving customer’s problems in a unique way at a competitive price). One unique aspect of Marco is that we offer full-service in-house development and production of products and department layouts in any material or finish (wood, metal, or plastic).”

What were the challenges you were facing in the design and manufacturing process? How do your processes/workflow get enhanced thanks to SWOOD?

“We were always under pressure from production and struggling to keep up with drawings and programs. We were also plagued with issues getting through to the shop due to all the manual translation and rekeying of data. With SWOOD we have very high fidelity from screen to machine, what you see is what you get. Now we do a virtual review process where everyone signs off on the model in SOLIDWORKS and we quickly and accurately deliver production paperwork and programs to manufacturing.

“We have effectively error-proofed the process from screen to machine while reducing the time to complete the work by about 6X.”

We also do a lot of copy/tweak designs where we start from an existing product and create variations of it to meet certain customer needs/customizations. Since the CAM data lives in the SOLIDWORKS file, the designer carries it over naturally and the programmer’s work is nearly done, just a few simple steps to rebuild the parts and verify everything looks good. Now that we’ve got most of our active products converted to SWOOD, the reduction in time is massive (leads to more responsiveness to customers which is our competitive advantage).”

Which features and services from SWOOD helped you to enhance this process, and how?

“Feature recognition, machining libraries, and the toolpath/CAM info living in the SOLIDWORKS file is the key to make SWOOD stand out as the ideal solution for us. Also, the SWOOD Reporting feature, and the Nesting feature enhanced our abilities to make programs quickly and efficiently and get the correct documentation to the floor as effectively as possible. We’ve eliminated all rekeying of dimensions and data so it is much faster and there are no typos or translation problems.”

How did SWOOD integration in your internal process go?

“We use SWOOD as a SOLIDWORKS add-in to create our nested router programs as bpp files, csv files that are imported directly into the beam saw optimizer, panels lists that go to each workcenter tailored to just the parts and information they need (parts for each machine, material and edge treatment information to the edgebander, moulding parts and dimensions to our mill). Other than the assembly drawing, all production programs and paperwork are delivered from SWOOD in the design report package. We have also made use of the board libraries to capture the MRP part number for raw material and estimate cost of the projects based on material usage.”

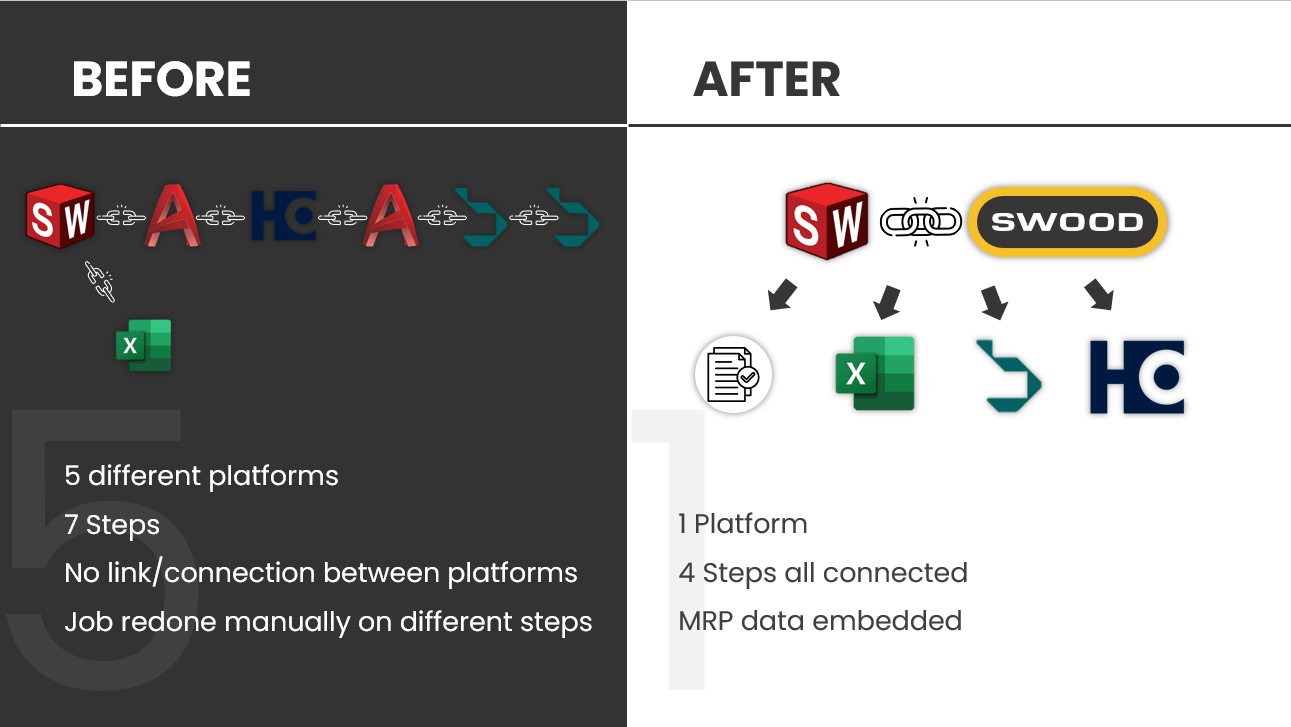

WORFLOW EVOLUTION

“Near perfect fidelity from screen to machine with nothing lost in translation all while reducing the time it takes to process fixtures (6X reduction). Drastically reduced time and rework to create variations off existing products, the programming work is already done. Clean paperwork tailored to each workcenter with no rekeying of information. Materials libraries to standardize thicknesses, finishes, and eliminate confusion on the shop floor and research by our sourcing team, the specific Item Number of the raw material is associated with each board and edgeband in the library. The designer just drags and drops it onto the part and all the details come with it.”

How it is done in the workshop?

“SWOOD posts native bpp files that are loaded into the controller at the machine using BiesseWorks without any modification required. The operator can load the program and trust it will produce the parts safely and accurately.

The beam saw uses CutRite to optimize daily batches. CutRite imports csv files that were auto-generated using SWOOD as part of the design package and have all the needed information for the optimizer and operator.”

What would be THE thing about SWOOD?

“The thing about SWOOD is the speed and flexibility of the tools and that I can trust it will deliver accurate paperwork and machine code to manufacturing. It is designed for our industry and has all the features you need in a very simple, visual, drag-and-drop interface.

It used to take all day to get a list of orders ready to be cut and we would struggle to meet production’s needs. Now we are actually mining for ways to do more for production and deliver better and better information. We’ve gone from being a roadblock to becoming a proactive partner in continuous improvement.”

SWOOD implementation process? (Time, how, who, challenges and successes, support from EFICAD …)

“I believe we made the purchase at the end of 2022 and went through user training in December of ’22. We were through the training and testing of the post processor by the end of January. For the next few months after that we were testing on live product and making refinements to the reports and paperwork.

At this point we have all our active products converted and are seeing the benefits of building on products that are complete and up-to-date with SWOOD (the copy and tweak process I was talking about earlier). We still haven’t leveraged the design tools beyond the board and edgeband libraries. That will be coming this year. I’m looking forward to our next breakthroughs in using SOLIDWORKS and SWOOD to continue Marco’s growth and deliver the “perfect package” to production.”

Anything else you would like to share?

“I do feel like SWOOD is the best solution on the planet for what we’re trying to do (industry and product mix). I’ve been at 3 different companies in the sector and have brought SWOOD and SW into all of them. I can’t say enough good things, I am a big fan of your product. Nice work!”

What’s Next?

“The next steps for us are to build the connections library and start using library components with the locating features built in. We do a lot of Dado/Rabbet construction, and it is time consuming to add in the dado features with proper clearances for materials and to keep all the designers using the correct dimensions. Having a drag-and-drop solution that applies the dimensions from a library will be a huge improvement. Having library parts like drawer slides and hinges add the location drill holes/features in the panels will also be a great time saver and drive consistency for manufacturing.”