The furniture industry has historically gone through a lot of changes. We were using carved stones in earlier epochs to have places to sleep and even to eat. Because of the evolution over the years, especially in modern years, the concept of functional products in households exploded while keeping the artwork aspect of the earlier era. In this article, you’ll learn about a brief industry about the industry and how it inspired us to create SWOOD Design, a 3D furniture design software.

2. Standardization of the furniture products

1. Handmade creation of furniture

Furniture making is a long-standing practice. For centuries it was crafted by hand, and indeed it is the craft that has determined how we understand the furniture available today. Today, because of craftsmanship, we can still imagine our custom-made furniture, which can be adapted to our interior in terms of both size and style. It is also through craftsmanship that wood has become the main material for furniture. Therefore, we still find a lot of wood in our furniture today, even if it is just decoration on particleboard.

Before they were called woodworkers, carpenters, and cabinetmakers, they were outstanding technicians with exceptional know-how, and they were even artists. They spent an enormous amount of time at their drawing board designing their furniture, but they spent just as much time making it, which was mostly done by hand. We didn’t even talk about material yield. The furniture that came out of the workshops was therefore often unique, but very expensive.

Today, there are still furniture craft-workers, but their numbers are much smaller, and they have focused on high-end niche markets.

The industrial era then took hold in all sectors, and the furniture industry was no exception. However, the furniture industry has been very difficult to industrialize, perhaps because of its historical offering that leaves so much scope for customization. Perhaps also because of the material wood, which is heterogeneous and difficult to master with many intrinsic constraints. For example, wood shrinkage, knots, or resin pockets make it a nightmare for an industrialist who wants to guarantee a certain manufacturing consistency in his products.

2. Standardization of the furniture products

It was with the democratization of wood-based panels (plywood, particleboard) that furniture became a major industry. These products made the material wood “manageable” by imposing fixed dimensions that varied little.

With the mechanization and industrial techniques of other sectors, the price of furniture has become much more affordable than before, which has revolutionized the sector. Design logics were completely revised: Fixed ranges were designed by optimizing the material to the maximum in a very short machining time, allowing the design time to be quickly made profitable on standard furniture that would be sold in thousands of units. The sector used ERP systems to manage assemblies and sub-assemblies, raw material, and finished product stocks.

3. The return of customization in the furniture industry

However, the standardization of furniture brought its disadvantages. Customers soon realized that all their furniture was identical to that of their neighbors, leaving hope for a return to customization. Manufacturers mass-produced to “make their production tool profitable” but found themselves with huge stocks of work-in-progress and unsold finished products. First, these stocks took up a huge amount of space, even with kit furniture. Second, many smaller companies could not cope with the cash flow impact of these stocks.

Today, with real market demand for cheap bespoke furniture, it is entirely possible to offer highly customizable products within an attractive price range, and we will see how and with what tools!

Today’s customers want quality and customization, but they still want to pay less for their furniture. We are going to see that this is quite possible thanks to a tool that might surprise you:

A powerful furniture design software: SWOOD Design.

4. SWOOD DESIGN, a furniture design software

When we think of a woodworking or furniture design software, we often imagine a rather outdated program that can hardly model a few pieces of furniture in volume. However, a real intelligent furniture design software can, and should, do much more than that!

5. Speed and reliability in designing furniture

If we want to offer highly customizable furniture products while remaining in an attractive price range, all our tools must be selected according to just two criteria: speed and reliability.

When you think of designing furniture as the old craftworkers did, it means that each piece will have to be designed from scratch, ensuring that the design rules specific to the industry and specific to the company are followed. This is ultimately the most time-consuming task.

Even when you take this long time to make a good design, the client can often change his or her mind concerning the dimensions, the height of the drawers, and the type of material used. As a result, start all over again with each new request for modification.

In a perfect world, smart furniture design software would integrate all the technicality and expertise of the company to simply design quality furniture. Routine projects would be created in record time, and the same software could create special pieces from scratch at the customer’s request. Modifications would be made instantly at the level of a room, a piece of furniture, or even the entire project. Once the order is placed, the projects could be transmitted to the manufacturing software (CAM) as they are with no additional features. Seamless integration with the company’s ERP system would take place. A set of documents would be generated with a single click to send to production (programs, drawings, bills of material, cuttings, hardware list, labels, etc.).

This kind of program already exists in the market, and SWOOD Design is a good example.

6. SWOOD Design, a parametric furniture design software

Most of the so-called “Classic” design software allows to draw any part and assembly from A to Z, it offers a 2D or even 3D visualization of wood projects. Although this speeds up the design process compared to hand drawing, such software only executes the designer’s instructions. And the designer must rely on his or her skills to draw technically coherent projects in line with company practices.

In contrast, there are so-called “Parametric” design software packages. This software has a completely different approach. It allows integrating the technicalities and specificities of the companies and thus really speeds up the design flow. This type of software seems rather optimal only when there are no specific custom designs to be made. Indeed, the design possibilities of the “Parametric” software are very limited and dictate that the projects do not go outside the classical design cases.

SWOOD Design is a compromise between the two types of software. Its “Parametric” side allows quick design workflows while guaranteeing perfect technical consistency. Its core design platform, SOLIDWORKS, gives it all the advantages of “Classic” design software by offering endless design possibilities to meet the most demanding bespoke requirements.

Ainsi, si on compare le flux de conception de trois entreprises qui acquièrent chacune un nouveau logiciel de conception : un logiciel de conception « Classique », un logiciel de conception « Paramétrique » et enfin SWOOD Design, on se rend compte qu’au début le logiciel « Classique » est plus rapide à mettre en œuvre. En effet, la formation est relativement rapide et il n’y a pas besoin d’intégration technique. Il est donc prêt à utiliser.

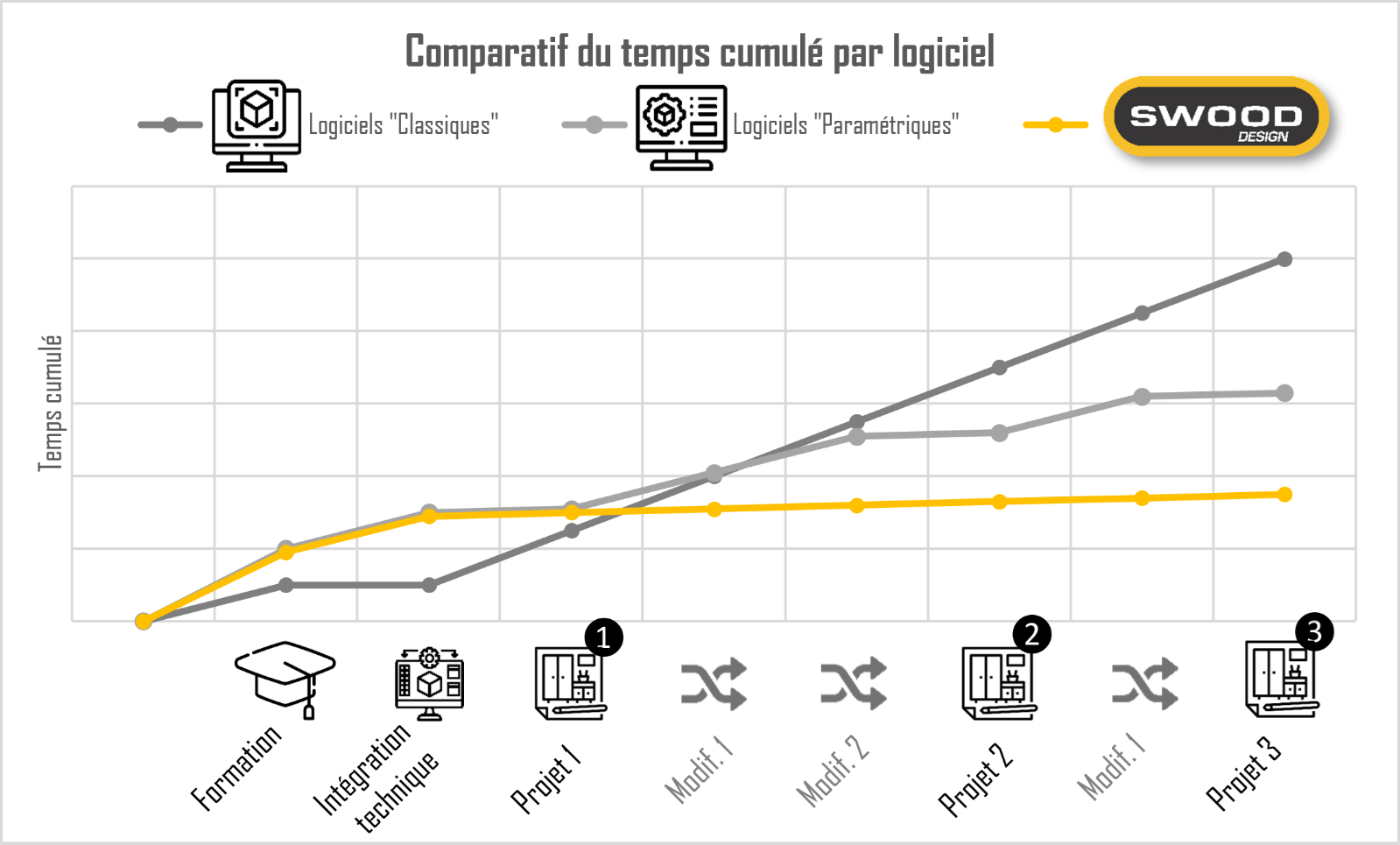

For example, if we compare the design flow of three companies that each acquire new design software: “Classic” design software, “Parametric” design software, and finally SWOOD Design, we find that at the beginning the “Classic” software is quicker to implement because training is usually relatively quick and there is no need for technical integration, so it is ready to use. Second, this software is still very slow to use, whether it is to create or change client projects. For this reason, the “parametric” software and SWOOD Design are very good at speeding up the design flow. Finally, when a special request is made for a project or a project modification, this is where SWOOD Design stands out against the “Parametric” software.

7. A unique wood design software

In conclusion, it can be said that SWOOD Design stands out from the competition by integrating the advantages of both ways of designing and avoiding their disadvantages.

SWOOD Design does not have a magic algorithm, its architecture has only been thought differently from the usual software on the market to adapt as much as possible to the unique specificities of each company, to drastically reduce the design time, and finally to face the particularity of each customer request.