Over two decades ago, Nicholas Tvrdeich, the owner of Francis and Company in Griffin, Georgia, USA, embarked on a woodworking venture out of passion for the craft. Starting with furniture projects, Francis and Company gradually expanded its expertise to include residential cabinetry, front entry doors, and carving. The company has a team of five skilled individuals between their wood and metal sides.

About Francis & Co

Industry – Custom Millwork

Size – 1-9 employees

Location – Georgia, USA

Used case – Design and manufacture

Products used – SWOOD Design, SWOOD CAM & SWOOD Nesting

Francis & Company initial challenges

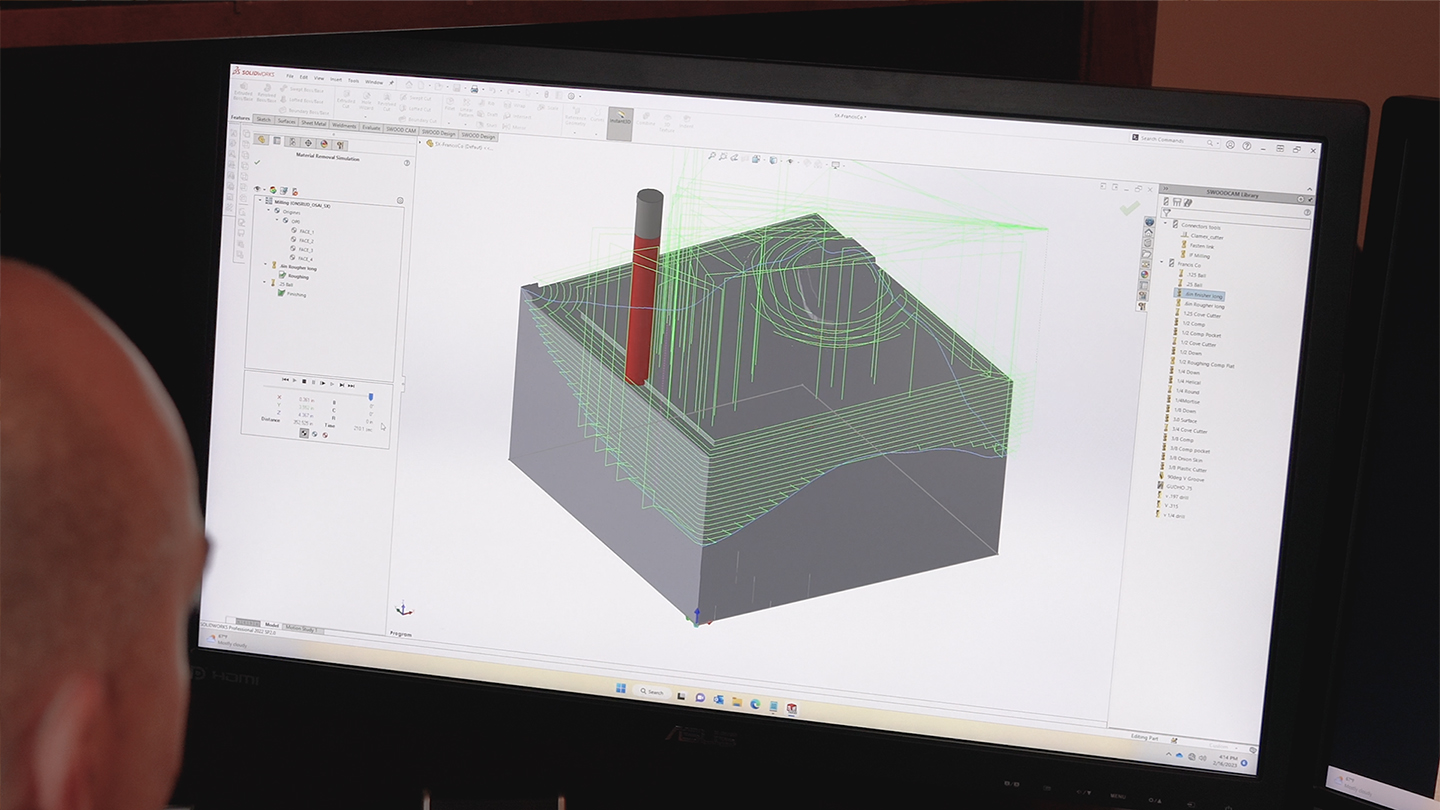

As Francis and Company expanded, managing complex projects involving 3-axis and 5-axis work became increasingly tricky using their existing software. “Any kind of carving, any radius work, bowls, anything that required 5-axis work, we couldn’t use the initial software that we bought,” explains Nicholas. “We had used 2 to 3 different software over the years.”

The team found it difficult to efficiently generate 3D solids despite the assistance of a second software. The entire process was slowed down by the need to import and export files using SOLIDWORKS to compensate. Additionally, sharing drawings with customers took much work involving multiple software.

A solution adapted to Francis & Company needs

The company’s design and manufacturing processes received a significant boost when SWOOD stepped in and made a positive difference. Implementing SWOOD, a fully integrated SOLIDWORKS add-on, transformed Francis and Company’s workflow.

Nicholas highlights the advantages of the software: “So in the design process, in using SWOOD, the very first time we started using it, we realized that it was going to basically streamline our manufacturing process.”

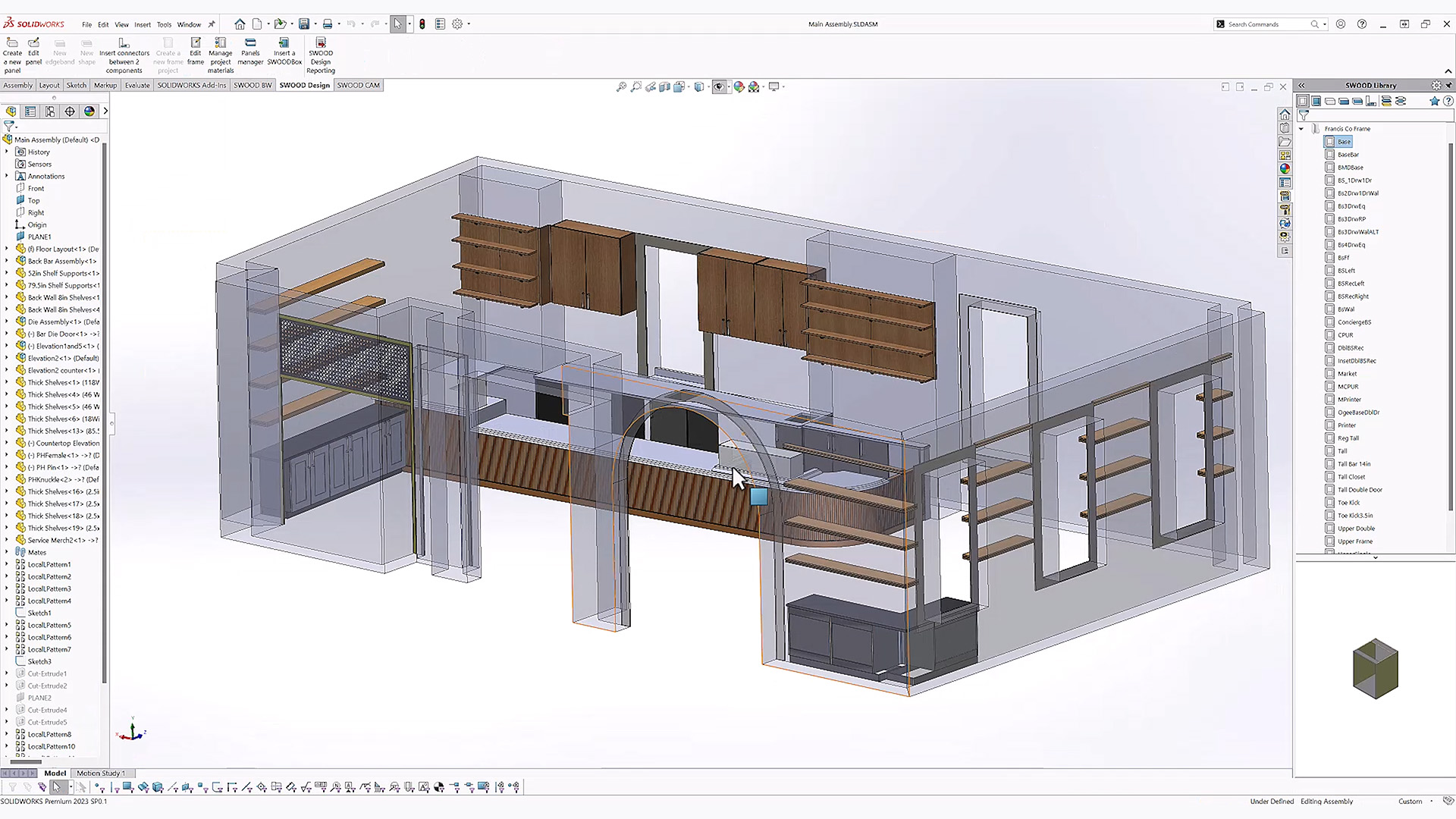

SWOOD empowered Francis and Company to realize hotel cabinetry projects with greater precision and control. Nicholas explains, “It allowed us to use different materials, different laminates, different edge banding profiles. It really allowed us to look at the project in a 3D manner within the design process to see what mistakes we were making.”

SWOOD’s benefits extended beyond design to the manufacturing phase. Nicholas is pleased with the connectors feature: “One of the benefits of the connectors was, especially with our drawers, we were able to machine the drawer parts with confidence. We can see our slides; we were able to choose different manufacturers for the slides that we use”.

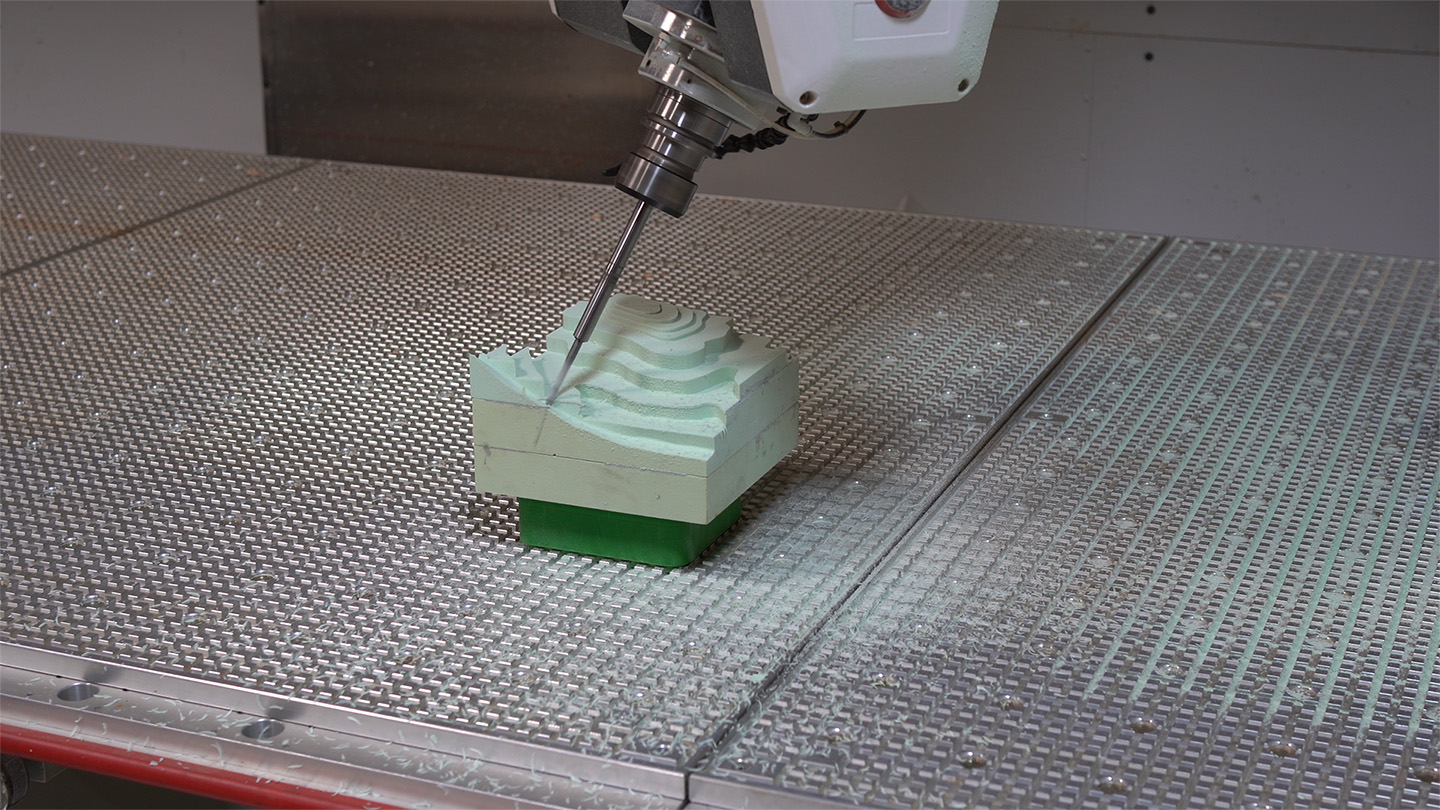

A significant advantage of SWOOD for Francis and Company was eliminating intermediate steps. Nicholas enthuses, “The fact that we’re able to take it from the design process directly to the machine. There’s no in-between software that we must use to basically streamline the process. It’s all in one step.”

Improved efficiency, control, and communication

By implementing SWOOD software, the company achieved tangible improvements in efficiency and control throughout its manufacturing process.

SWOOD’s 6-face nesting feature allows the company to flip sheets effectively and work on both sides of the panel, saving time and material. The software also allows for precise control over dowel insertion, including setbacks and alignment.

By inserting dowels from SWOOD Design, designers can see the project’s digital twin in SWOOD Nesting, allowing machining preview. Nicholas affirms, “It also allowed us to look at the dowels in 3D process and align them from one side to another, which we weren’t really able to do with previous software.”

SWOOD also improved communication both internally and externally. In the past, the company faced the risk of errors and delays when exporting files between different software programs. With SWOOD, the company can share files directly between designers, machinists, and clients, ensuring everyone is on the same page throughout the entire project.

Enabling expansion and customization (one-off projects)

Francis and Company is now expanding its product offerings to include a wider range of furniture, such as commercial banquettes and FF&E (Furniture, Fixtures, and Equipment) items. “SWOOD allows us the flexibility to move into those items seamlessly. We are still doing a high volume of commercials, which SWOOD is allowing us to do.” Nicholas confirms.

Conclusion

SWOOD has undoubtedly played a significant role in improving Francis and Company’s design and manufacturing processes. With its versatility and adaptability, SWOOD can respond to the needs of many sectors. Its ability to streamline processes, improve efficiency, and enhance communication makes it a valuable tool for businesses of all sizes.