1. What is SWOOD 2022?

SWOOD 2022 is the latest version of the leading 3D CAD/CAM software for the woodworking industry (fittings, furniture, construction, etc.).

This version includes many new features that will make life much easier for its users.

Once again, the software developers at EFICAD have expanded the range of design and manufacturing options for wood projects, while simplifying and speeding up the workflow. SWOOD’s unique features will save companies valuable time by providing more relevant automation.

2. So how was the upgrade developed?

SWOOD software is not simply sold! For each project, a team is deployed to analyze the company’s needs and propose the most suitable solution to the client. Then, technical assistance is provided by our partners network or EFICAD to configure the software solutions as closely as possible to the company’s technical needs.

SWOOD CAD/CAM software development has always been based on the needs of wood products & furniture manufacturers.

Today, the SWOOD software portfolio is used in over 52 countries and counting. This strong international presence ensures that the features of our software serve many companies and all local aesthetic and functional trends. Thus, the functions developed throughout the different SWOOD versions extend to all the techniques of the wood industry.

Whether it is for the manufacturers of CNC machines that will machine the wood parts, or for the hardware manufacturers that will assemble them, the SWOOD development team makes it a priority to integrate the latest technical innovations from all the players in the wood industry.

The characteristic that distinguishes SWOOD from its competitors is the parametric design of wood projects. In brief, the general models defined by our users, such as a piece of furniture, can be reused in many customer projects where customization (materials, assemblies, dimensions, position, etc.) will be carried out in an instant thanks to simple drag and drop options.

3. What’s new in SWOOD 2022?

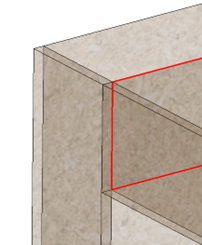

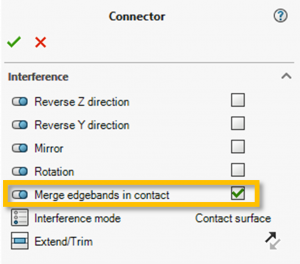

Edgeband thickness taken into consideration for connector insertion

SWOOD Design allows the management of edgebands, connectors (joints) between panels and many other functions related to furniture.

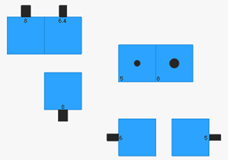

When inserting a connector between two panels (by drag and drop for a single connector or with the connector manager for all the connectors in a project), the software detects the contact surface between the two panels to be connected to insert the connecting elements (dowels, eccentrics, etc.) dynamically (number of elements, centre-to-centre distance, distance from the edge, etc.).

It is now possible to choose whether to include the thickness of the edges in this detection zone.

This new option has the advantage of managing the integration of assembly elements more precisely and of being able to create rules for the arrangement of these elements without having to enter the thickness of the edges.

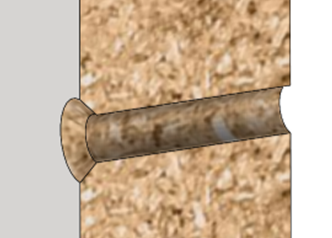

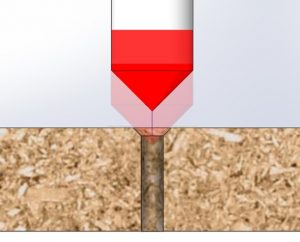

SWOOD Design: Chamfered holes in SWOODBox milling

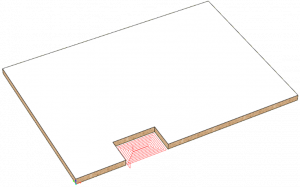

A SWOODBox is a unique element of SWOOD Design software. It allows many functions to be added to a wood project. For example, a “drawer” SWOODBox inserted by drag and drop into a cabinet will add a drawer model from a hardware supplier such as Hettich or Blum by adapting to the space available in the cabinet. It will integrate all the hardware necessary for the drawer to function properly and will automatically generate the machining specific to the drawer in the cabinet (holes, grooves, pockets, etc.).

Since SWOOD 2022, it is now possible to add chamfers to the SWOODBox holes by simply showing the width and angle of the chamfer to be generated.

The advantage of this option is that it is possible, for example, to integrate the screw heads into the machining of a panel.

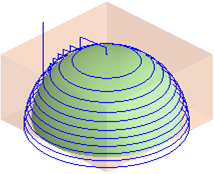

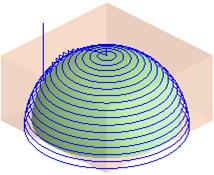

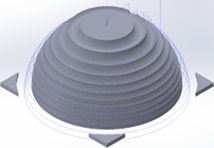

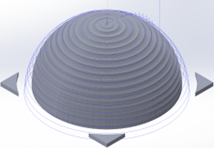

SWOOD CAM: Optimization of 3D surfacing trajectories.

When you want to machine a 3D surface, you first do a roughing cycle of the stock, which will make the job easier. Then, a ball-nose cutter will perform 3D surfacing. The tool will make trajectories that will reveal the desired 3D surface.

In SWOOD CAM, the 3D surfacing paths have been enhanced with a new option. As of version 2022, you will have new features, allowing these toolpaths to no longer be spaced in planes of equal distance, but in planes of equal minimum distance.

This new feature allows the workpiece to be machined as close as possible to the desired shape and reduces the number of sanding operations.

SWOOD CAM: Machining Strategies

SWOOD CAM: Chamfered holes

In addition of the SWOOD Design new feature “Chamfered holes in SWOODBoxes”, the automatic drilling of chamfered holes allows drilling operations to be programmed directly with a chamfering tool in SWOOD CAM.

The primary advantage of this new feature is that drilling operations with drill bits for the holes and chamfering operations with a chamfering tool can be integrated directly into an automatic drilling machining strategy. Once the machining entity has been created, a simple drag and drop of the latter onto a workpiece will detect all the holes to be drilled and will program them with the drill bits. The holes to be chamfered will also be programmed.

SWOOD CAM: Auto defined aggregate type

One library in SWOOD CAM is for the definition of aggregates, where our users will define drilling blocks , angular aggregates and edgebanding aggregates according to the characteristics of their machines. Technicians will define each spindle of their aggregates so that they match their machining capabilities of their CNC machine.

The new ‘auto defined aggregate type’ option allows an empty unit to be created that will single-handedly detect all the holes to be drilled on a part. It will then automatically create all the spindles needed to machine them. With this option, it is the workpiece that defines the spindles that are needed, not the other way around.

This new feature can be very useful for companies that have several CNCs and want to make sure they don’t forget any holes to drill. To do this, they will first program their holes with this type of unit. They will generate the program and send it to one of their machines, which will send back an error message if a spindle is missing to complete all the holes.

SWOOD CAM: Outline open pocket

The “Outline open pocket” operation is a contour operation. It is used to machine only the inner areas of parts that pass through (such as siphon hole for sink shelves).

The contouring operation machines the entire inner area as if it were pocket machining (hence the name), taking care to turn all the material into chips and not leave scrap wood.

This new operation is relevant for companies using panel CNCs (where the workpiece moves around fixed tools) thus avoiding machining problems that generate wood waste.

SWOOD CAM: Staydown contour

The “staydown contour” strategy is also a part contouring operation. It was created for users of Nesting machines and processes because it allows contour paths to be generated without lifting the tool (if the parts are close enough together).

Besides a considerable timesaving advantage (up to 20% of machining time saved), this operation allows the parts to be kept together as long as possible. It, therefore, Ensure a good holding of the small parts on the flat table nesting router.

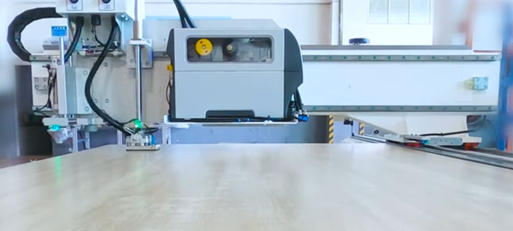

SWOOD Nesting: Optimal holding and Library of Part Types.

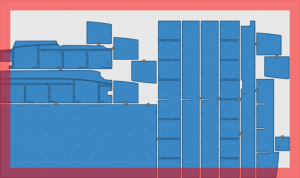

Another new feature is the SWOOD Nesting Part Types Library, which allows the improvement the holding of nesting parts on flat table nesting machine.

A set of options is included in this library to optimize the holding of the parts:

- Avoiding small parts on the edge of the board:

Defining an external distance where smaller parts cannot be placed, as it has been noticed that small parts on the edge of the panel have a much greater tendency to come off the vacuum table.

- Machining order sorted by size:

Definition of the machining order, starting from the smallest part to the largest.

- Optimized tool approach and retraction:

Optimal positioning of the lead-in points for contour operation that allows each workpiece to remain on the suction table for as long as possible.

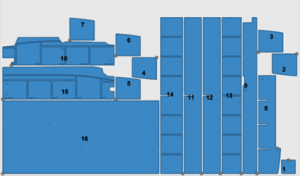

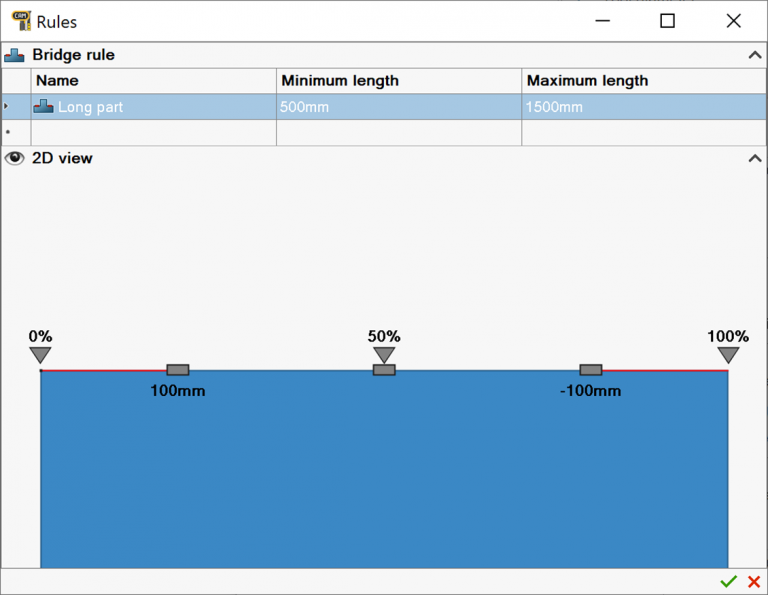

- Automatic bridges according to the type of workpiece:

SWOOD Nesting: Labelling

SWOOD Nesting: Panel stocks

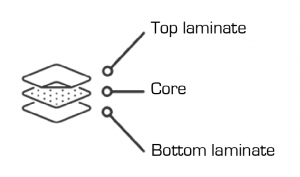

SWOOD Nesting offers, as of version 2022, the option of nesting each layer of a multi-layered material separately.

This option is useful for companies using the nesting technique and that work with multi-layered panels made of core material in between 2 laminates.

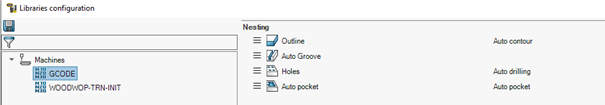

SWOOD Nesting: Automatic insertion of machining strategies.

It is now possible to assign in advance (in the brand-new machining library of SWOOD Nesting) all the automatic machining entities (auto contour, auto groove, auto holes, auto pockets) for each post-processor that you use.

The advantage of this other new feature is that it automatically generates (either partially or totally) the machining of each nesting plate. Once again, this new feature will save companies’ precious time.

SWOOD Nesting: User experience improvements

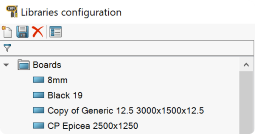

- Search bar and filter in the Board Library:

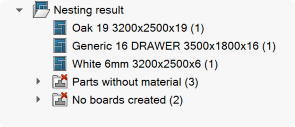

- Clear error message in the Nesting tree view:

- Replacement of part names by numbering:

Identification of different assemblies by colors:

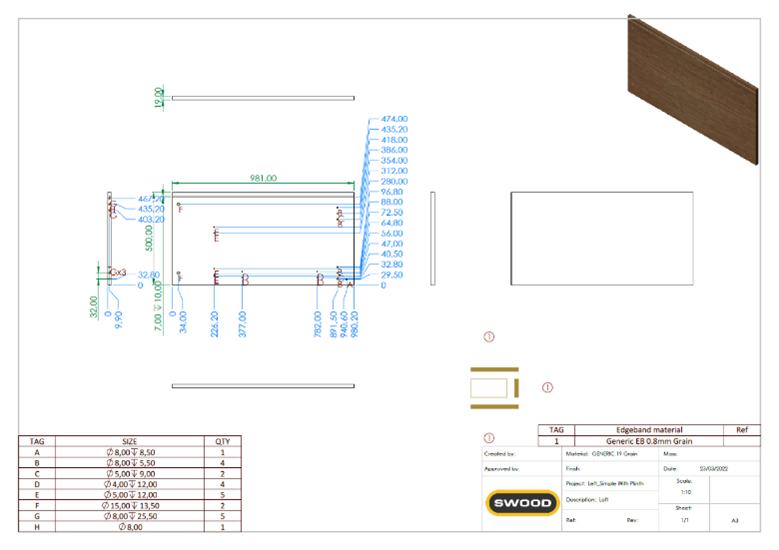

SWOOD Report: Configurable and automatic generation of panel layouts

These drawings can be generated at the level of a panel, a cabinet, or even a complete layout. It is also possible to filter the drawing generation, or not, according to a custom property in the SOLIDWORKS part (to not generate drawings for other material such as glass shelves, for example).

The advantage of this new feature is that it saves a lot of time on repetitive tasks to create drawings for companies that need them for their production.