Precision, efficiency, and innovation are paramount in shopfitting to compete with the ever-changing market. SWOOD streamlines the entire process from initial design to production, making it easier to cover your product range with parametric tools, advanced material management, and precise project layouts.

The woodworking-based features provided by SWOOD, coupled with SOLIDWORKS, allow you to create custom shapes and produce them in numbers with this parametric solution.

1. Modify your shopfitting project elements at once.

SWOOD allows you to create entire rooms using the layout mode (kitchen, store fitting, dressing room, and so on) by reusing your frames’ templates. You can quickly respond to customer requests by changing the dimensions of the various pieces of furniture that make up the assembly.

2. Design efficiently using ready-to-use library components.

SWOOD streamlines design by customizing or configuring the behavior rules for your library elements (connectors, SWOOD Boxes, etc.). Insert your elements faster with predefined rules and produce more reliable products. With SWOOD, you can have the ability to save your company know-how and maintain consistency in your projects by creating your library elements. Drag-and-drop hardware components such as drawers, hinges, shelves, dividers, cable grommets, etc., and use your libraries’ intelligent component capabilities. All library-saved elements integrate their associated machining, saving time and reducing the risk of input errors manually.

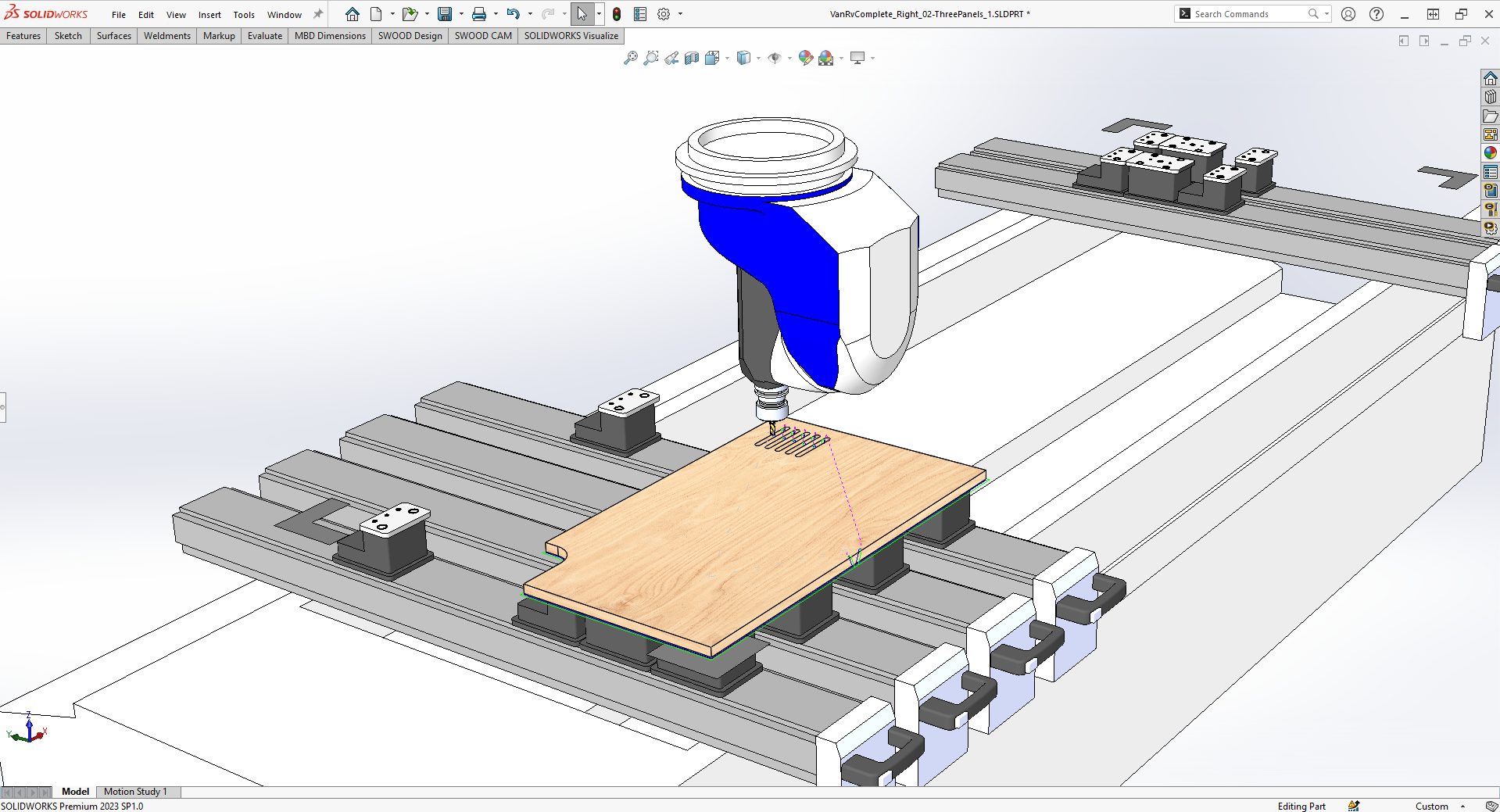

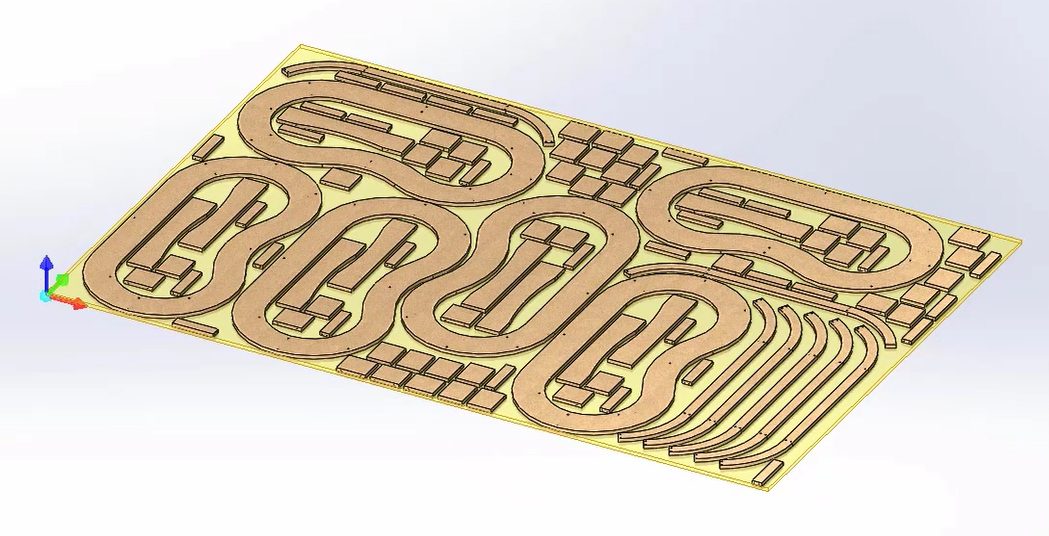

3. Produce and nest your shopfitting projects with efficiency!

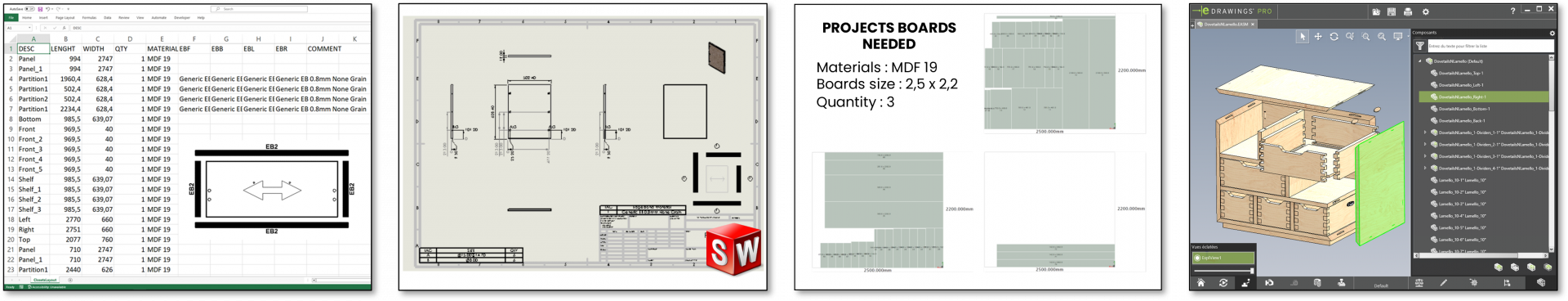

Generate programs and workshop documents from 3D design projects and optimize your production. Benefit from wood-specific machining strategies, offering point-to-point and nesting capabilities. SWOOD quickly identifies 3 and 5-axis machining operations, optimizing tool paths based on flexible strategies. Design changes are instantly recognized, updating tool paths in just one click.

4. Complete workflow control with leading CNC integration.

Integrate SWOOD effortlessly with top CNC machines like HOMAG, SCM, BIESSE, and others. Take unprecedented control over pre-production simulations and the entire production workflow and elevate your manufacturing efficiency.

5. Enhance project coordination and data exchange.

The software automatically collects all design element parameters, generating a project report for production, including material and hardware requirements, machining programs, cutting lists, etc. Export these reports in any format usable in your workshops. Any parameter change made in the design is applied to programs and documents, enabling their generation in one click.

Customer testimonial

“SWOOD allows us to create customizable libraries and easily discover the quantity of materials we consume. The software has already made our design and production process more efficient.”

Gerolimos Nikitas, Industrial and Product Designer, WESTAND – shopfitting Greek company

With the advantages and features offered by SWOOD, many shopfitting companies, big or small, have optimized their workflows from design to manufacturing and have enabled automation in their repetitive processes. SWOOD is the ideal solution for your innovative shopfitting projects.