Did you ever dream of using a design element that “thinks” like you? An element that adapts to its environment and applies the design rules of your company.

This element exists and is called SWOODBox!

In this article, we will explain what makes the SWOODBox a highly efficient design element that can be applied rapidly and that integrates the entire range of technical combinations you offer your customers.

In addition, we offer you the opportunity to try it out for yourself by providing you with a complete tutorial for creating a SWOODBox from A to Z. (Video below)

1. SWOODBox

Capabilities of a SWOODBox

Adaptation to wood projects

Whatever the dimensions of the furniture into which a SWOODBox is inserted, it adapts to the volume or surface into which it is inserted. As a result, the design is parametric and can be adapted to each new project.

In addition, SWOODBox can embed a configurator on which many variables will allow to adjust the design. This feature makes it possible to generate a very large number of design combinations from a single SWOODBox.

The conception of a SWOODBox can involve the assembly of many components. Often, these components are provided by leading hardware partners which 3D models are downloaded and integrated into the SWOODBox from the SWOOD Design Library. This SWOOD Design library is then populated and updated for all customers of the software.

Once the model is fully designed, the designer can run a SWOOD Design report, and the software will generate a detailed bill of materials with the associated cost.

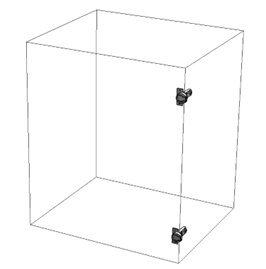

When we drag and drop a SWOODBox to a volume or a surface, it also includes machining. For example, besides importing wooden panels that will serve as shelves in the assembly, a shelf SWOODBox will automatically create holes for the shelf pins on the surrounding panels.

A SWOODBox can generate drillings but also any kind of extrusions such as grooves, rebates, pockets even free-form extrusion. These machining operations can be set up on all six sides of the SWOODBox volume.

4. Modifying a complete model in real time

Designing wood projects can be a rather time-consuming task. It becomes even more demanding when the clients change their minds several times about the design.

One solution would be to have the customer validate their furniture design using an “aesthetic” model only, without all the hardware and machining involved. However, the disadvantage of this solution is that there is no guarantee that a choice made by the customer is technically feasible, and the final design of the model remains to be completed at the end, with all the elements absent in this “ light “ version.

With SWOODBox, any modification is quick thanks to drag-and-drop insertion. Each of these modifications is complete because all the technicality is integrated inside the SWOODBox. You can therefore make live modifications and immediately see if the project is realistic or not.

5. Behind the magic of SWOODBox

So, the question is, why do SWOODBox work so well and how do they work?

Parameters: The link between the 3D model and the user

SWOODBox parameters serve two purposes: to modify the SOLIDWORKS 3D assembly and to allow the user to interact with the SWOODBox.

These parameters come in several forms, such as dimension, angle, or number variables, which can directly take control of existing SOLIDWORKS dimensions.

Other interface parameters, such as drop-down lists or checkboxes, allow the user to choose how they wish to set up the SWOODBox.

These variables, therefore, integrate seamlessly within the SOLIDWORKS software and provide a powerful interface between the user and the parametric 3D model.

6. The Script: The brain of the SWOODBox

Based on the control and interface variables, the SWOODBox designer can create design rules directly in the “Script editor” wizard.

This code editor may look overwhelming at first, but it is simply the area where logical rules are described.

The SWOODBox designer predicts the different use cases with conditions, and for each condition, indicates to the software what to do with precise rules.

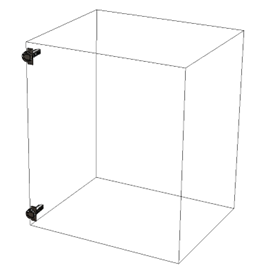

Here’s a concrete example: a designer wants to create a SWOODBox of hinges from his hardware supplier’s catalogue. As seen in the previous sections, he will integrate the 3D model of the hinges from the supplier’s site into his SWOODBox assembly. Then, he will create different variables to control the position, configuration, and number of hinges.

With the help of the design rules from the catalogue, such as the number of hinges for a door height, he will create different conditions in the script and change the value of the control variables accordingly.

In the script, one has access to all the variables created by the designer, as well as all the existing variables.

The script also allows us to predict configuration “errors” and to display custom error messages to users. In our example, an error message could be displayed if the door height is too high and no longer meets the requirements of the supplier catalogue.

7. How to go further

Step 1: Adapting existing SWOODBox to your use

One of the easiest ways to make an existing SWOODBox your own is to adapt the default settings to your use.

From the standard SWOOD Design library, provided with the software, a user can adapt existing SWOODBox to his or her use. Indeed, all SWOODBox in the SWOOD Design library are fully editable.

For some SWOODBox, the number of variables can be very large, and the script can be very long and difficult to understand. This can intimidate a novice user who might be hesitant to break the normal functioning of the SWOODBox.

For example, when taking a hinge SWOODBox provided in the library, it is possible that when inserting a hinge SWOODBox provided in the library, the hinge positions itself by default to the left with a distance of 50 mm from the edge.

If company practice dictates that hinges should be inserted mostly on the right and with an edge offset of 100mm, then there are only two variables that need to be changed in the SWOODBox : the “Side” variable and the “Distance to Edge” variable, to make it appropriate.

This simple change may seem trivial, but if it saves one minute for each SWOODBox insertion (because the user will not have to edit the SWOODBox and then change the parameters). Therefore,it will have saved a lot of time at the end of the project.

Step 2: Create your SWOODBox from scratch

Another way to save your business a lot of time is to create an original SWOODBox from scratch, considering all potential use cases.

Although more technical than customising an existing SWOODBox, this task is accessible to all, with little practice.

The first step is to draw up a set of requirements and constraints for the desired SWOODBox. For example, you want to create a shelf SWOODBox with a single shelf that can either be positioned centrally at all times or can be positioned from a distance of the bottom panel. Also it may or may not include the holes for the shelf pins on the sides.

Then the 3D elements are drawn in the SOLIDWORKS assembly.

Finally, the variables of the SWOODBox are created, and the script is written.

For you to practice with a concrete example, watch the tutorial video presented in this article. It details step-by-step the creation of a simple shelf SWOODBox.

Step 3: Leveraging the power of SWOODBox for a full-scale project with SWOOD Center

This SWOODBox logic, unique to SWOOD Design software, has been so appreciated by its users that EFICAD has developed a feature that allows to control and vary your design at a top-level. With SWOOD Center, it is possible to exploit the variables and scripting for a top level layout. Also, the “Configurator” part of the SWOOD Center is included in every SWOOD Design license.

Not just limited to wood material

Although created for projects with wood material, SWOODBox are now used in companies that process various other materials such as metals, plastics, and more. Initially, the transition was made in companies that use both wood and other materials. These companies found a cross-functional software with SWOOD Design. Today, many companies that do not process wood at all are making the informed choice for SWOOD Design and can exploit the true power of SWOODBox.

The parametric design logic of SWOODBox, a real design asset, goes far beyond the material being manufactured.

Not just limited to the furniture industry

SWOODBox were created to design furniture, but today they can be much more useful than that : they are only limited to the designer’s creativity, provided there is an advantage in integrating elements into a volume or surface.

For example, some companies have created SWOODBox which speed up the design of timber frame walls or partitions.

Many companies, out of the furniture or wood industry, have used the SWOOD Design parametric design software precisely because of the power and speed of SWOODBox.

Jonathan Fernandez

Engineer and Instructor at EFICAD