- Emmanuel

Discover SWOOD CAM

As any niche market, the wood industry has a lot of specification, especially in the production process.

All of them come in addition to the global challenges of a manufacturing company.

The efficiency is one of the key factors we need to focus on to design and produce quickly with a high reliability rate.

Thanks to its geometric analysis, SWOOD CAM, detects automatically several machining used in this industry such as contouring, pocketing, drilling, grooving, sawing and specific hardware milling (Clamex,etc.).

As its core is based on model analysis, you will have the opportunity to deal with several files format such as all the exchange file formats (.STEP,.sat,.x_t, etc.). The other advantage of this smart analysis is that it dramatically decreases the production errors.

Even the last-minute design changes are considered and are automatically updated in the program generation.

Automatic operation

SWOOD CAM also offers the possibility to define custom and complex strategic machining in a few clicks and keeps all this know-how in a library usable at any time with simple drags and drops.

It considers your material and especially modulate the feed rate based on grain direction on solid wood material.

Drag and Drop

This module also embeds up to five axis features as standard allowing you to manage all machines of your workshop / plants even on different machine languages.

On complex 5 axis parts which need to be double checked, we have developed a simulation feature with material removal and collisions detection.

Handrail simulation

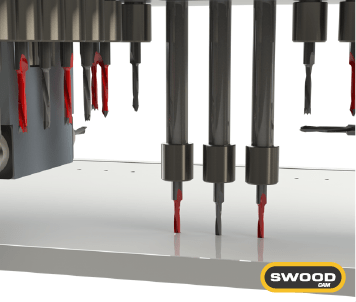

Our CAM solution also deals with specific woodworking tools such as drilling blocks, horizontal spindles, edgebanding aggregate, profiling tool for joinery purpose.

As a complete CAM software, we also provide a solution to the motorized table machine whether there be clamps, rails and suction pods system and laser system.

Windows milling

We always kept our solutions up to date with all the last machines technologies throughout the years (HOMAG, BIESSE, SCM, Morbidelli, Felder, Holzher etc.).

This allows us to generate programs for all numerical control machine brands in the woodworking industry up to five axes (WoodWOP, bSolid, BiesseWorks, Maestro, Xilog, TPA, NC-Hops, Gcodes, etc.).

Finally, we will obtain the highest efficiency from both modules SWOOD Design & SWOOD CAM.

Indeed, as we will use panels from SWOOD Design libraries, we will integrate our smart operations in these SWOOD panels and while we are designing, we are also creating our parts programs at the same time.