SWOOD 2024 is the last version of our all-in-one solution for woodworking professionals to design, manufacture, and automate their projects. Our team develops new features and enhancements based on industry needs every year.

This article highlights some of the main features present in the SWOOD 2024 version:

- SWOOD Design: Panel Cut & Panel Joint

- SWOOD CAM: 3D Finishing Feature – Edgebanding on CNC Machine – Clamex Machining with Cutter

- SWOOD Report Interface

Explore all the recent updates and learn how to use them by watching the “What’s New in SWOOD 2024 webinar” video:

This year, SWOOD’s parametric design software for the woodworking industry has been updated to optimize your workflow.

Speed up your Designs with the Panel Cuts Feature

Diamond-shaped reception desks, under-slope dressing, or any complex projects are now easier to design.

The feature simplifies panel cuts regardless of the intersection angle and eliminates the calculations required to connect two panels. This allows users to make accurate cuts even on complex, simplifying the design process.

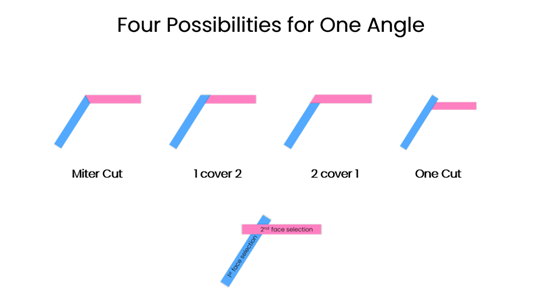

This cutting feature can be used on panels at any position and angle. Simply select the panels’ interference and choose the necessary reference; SWOOD will then automatically make the cut on one or both panels. Any modifications, angles, offsets, and more will be updated in detail in the 3D design.

For each panel’s interference, SWOOD suggests connection options based on four different possibilities:

Easily Create Panel Joints

Introducing two new assembly options for wood connections: halved joints and tenon-mortise.

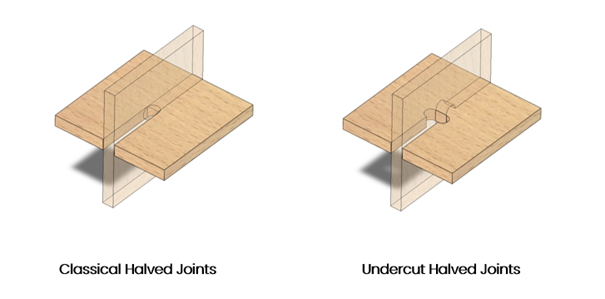

1. Halved Joints

Halved joints are a woodworking technique that interlocks two pieces of wood by reducing each piece’s thickness in half at the overlapping area, allowing the other piece to pass through. This method preserves the continuity of both pieces.

Two options are available: classical or undercut halved joints, which can be managed with offset and position parameters. Users have the flexibility to select multiple interferences to effectively create halved joints, a process that SWOOD has significantly simplified.

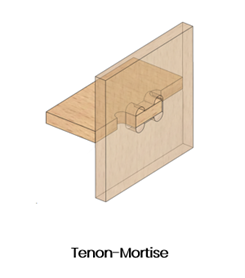

2. Tenon-Mortise Joints

Tenon-mortise joints are a traditional woodworking method for joining pieces of wood. The tenon is a rectangular projection cut on the end of one piece, while the mortise is a corresponding cavity cut into the other piece. This interlocking joint offers great strength and stability for robust furniture.

The connector library already allowed the addition of tenon-mortise joints in the previous version. This year’s update is specific to the CNC machine; it also embedded some different parameters to set the offset, quantity, lengths, and position of the tenon-mortise joints and the tools used by the CNC machine.

SWOOD CAM software constantly evolves to meet user needs and adapt to the manufacturing process, regardless of complexity.

Go further with 5-Axis Work

The year’s updates allow the user many possibilities with the 5-axis to manufacture complex and irregular shapes. Easily handle any surface and select the ones you want to protect or machine, leaving you in control of your production process.

The new 3D finishing feature is based on the 3D model, allowing accurate machining in three dimensions. This operation allows users to control their projects with a wide range of options to meet their specific needs in an intuitive interface.

Trajectories can be determined by surface selection based on the user’s choice. Areas and sketches previously designed can be easily added or removed from the machining, and transition paths between areas can be managed in advance.

To protect specific areas during the machining process, simply select the desired area in the interface and define the tool offset from the area.

Automatic Edge Banding on CNC Machines

SWOOD proposes deeper integration with CNC suppliers with a specific export for B-SOLID or WOODWOP to manage edgebands‘ embedded aggregated on CNC machines.

Export all edgeband information, including the edgebanding order defined in SWOOD Design for B-Solid and WOODWOP, at the moment.

The user can access all operations, such as contour, pocket, drill, sawing, etc., and new edgeband aggregate operations for contour, blowing, gluing, flush trimming, scraping, etc.

This advancement offers a solution to streamline the edge banding process by automating it on CNC machines and improves production efficiency.

Clamex Machining with Cutter

Since several versions, SWOOD supports the creation of blade machining for clamex fixings. This operation was already possible manually with a cutter.

With SWOOD 2024, it is now possible to machine them automatically with a cutter, whether in a 3-axis or 5-axis configuration. This new operation allows consecutive actions with the same tool, saving time during the machining process.

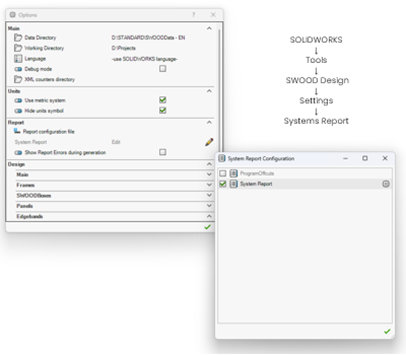

SWOOD 2024 introduces a new report interface, gathering all needed information in an easily accessible place.

Configurable production documents

SWOOD 2024 facilitates project management between your designs and your production with customizable online documents.

SWOOD allows you to generate a detailed report for production in an accessible place, including panel lists, cutting lists, bills of materials, hardware lists, programs, and more.

Customizable SWOOD Report

The reporting feature of SWOOD is now encapsulated within SWOOD as a feature. This structural enhancement enables any SWOOD user to access any improvements to the Report through a brand-new and configurable web-based interface.

It also offers users the flexibility to personalize how data and documents are displayed, incorporating the new documents available with the latest SWOOD update.

Intuitive Interface

Enjoy an intuitive interface and access any project information on any web browser.

Global settings such as report history, printer export, search bar, and others enhance the user experience. These settings allow easy navigation and visualization of production data.

This web-based interface offers the possibility to configure dedicated views thanks to configurable tables and filters with the possibility to export them in CSV format.

Bring Your Visions to Life with SWOOD 2024!

With its new functionalities and updates, SWOOD 2024 supports users in pushing the limits of design, manufacture, and automation, achieving projects with efficiency and accurate results.